In the highly competitive flour milling industry, operational efficiency and equipment durability make all the difference. At TC ROLL (Changsha Tangchui Rolls Co., Ltd.), the latest generation of high-chromium alloy mill rolls offers flour millers a powerful way to reduce downtime, lower maintenance costs, and improve output consistency.

Operational Challenges in Modern Flour Mills

Flour mill plants often face problems such as:

- Frequent roll replacements due to abrasive wear

- Irregular roll hardness leading to uneven product quality

- Production interruptions caused by maintenance and downtime

Traditional carbon steel or low-alloy rolls can wear down quickly under high-load, continuous grinding processes, increasing operating costs over time.

TC ROLL’s High-Chromium Alloy Solution

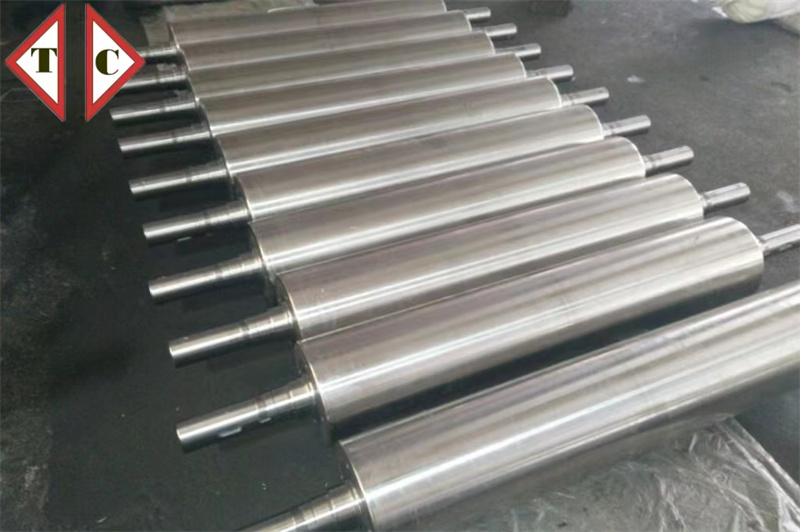

TC ROLL manufactures mill rolls using composite centrifugal casting combined with electric furnace smelting, forming a nickel–chromium–molybdenum alloy layer commonly 25 mm+ thick. This layer is bonded to a quenched and tempered steel core to achieve:

- Uniform hardness across the entire roll surface

- Outstanding wear resistance against abrasive grains

- Lower vibration and noise during operation

- Longer service life with improved running stability

This uniform alloy structure helps prevent surface fatigue and micro-fracture, directly reducing the need for frequent roll changes.

Practical Performance Benefits for Flour Mills

By switching to TC ROLL alloy rolls, mills typically experience:

- Longer replacement intervals → fewer shutdowns

- More stable roll gaps → consistent flour extraction rates

- Improved end-product quality → better customer satisfaction

- Lower maintenance labor and parts costs

Though the initial investment is higher than basic roll types, the total cost of ownership (TCO) is significantly lower due to extended service life and reduced downtime.

Implementation & Optimization Recommendations

To maximize performance:

- Track current roll lifespan and downtime impact

- Compare costs using TCO instead of purchase price alone

- Introduce regular surface and hardness inspection

- Apply predictive maintenance scheduling

TC ROLL’s technical support team can assist with selection, installation, and maintenance planning.

Post time: Nov-10-2025