ABOUT US

Breakthrough

Tangchui

INTRODUCTION

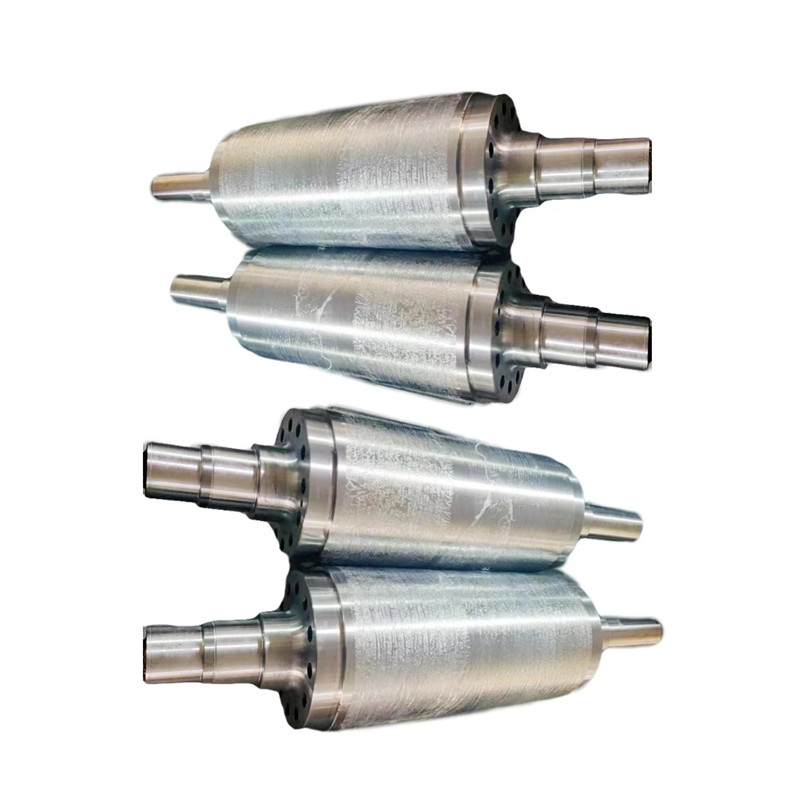

Changsha Tangchui Rolls Co., Ltd. is a professional manufacturer of mill rolls, located in Hunan Province, established in 1999, covers an area of 45000 square meters. Has more than 500 workers.

Tangchui is determined to become a professional Chinese provider of different rolls in different industries, and then to be the premier partner of global enterprises.

-

-%market share in China

-

-+technical experts

-

-+technical patents

-

-+Hot selling countries

products

Innovation

NEWS

Service First

-

Thank You for 2025 — Welcome, 2026!

With gratitude and optimism, we greet the dawn of 2026. The past year’s successes were made possible through your engagement, feedback, and unwavering support. As we look ahead, we are committed to deepening our collaboration, enhancing our responsiveness, and contributing to your long-term objec...

-

How TangChui’s Composite Centrifugal Casting Crafts High-Performance Mill Rolls

Changsha, China — At Changsha TangChui Rolls Co., Ltd., the journey from molten metal to ultra-durable mill roll is nothing short of a technological feat. Since its founding in 1999, TangChui has honed a composite centrifugal casting process that lies at the heart of its reputation for reliable...